Vetrofluid is Saving Runways from Ultra-High Pressure Cleaning

Ultra-High Water Pressure testing on Vetrofluid treated concrete has now been performed several times, for several different audiences because the engineers and executives cannot believe it when they are told just how much more abrasion resistant concrete becomes after Vetrofluid is applied!

These tests have been performed by airfield engineering firms, independent laboratories, and by airport construction and maintenance teams.

Vetrofluid Tested on a Live Runway

Rubber residue builds up over time, mostly on the touchdown areas of runways. This rubber can greatly reduce the friction coefficient of the runway surface, especially under wet conditions.

Airfield maintenance teams use ultra-high pressure water to remove this rubber, and paint striping as well and they have all seen how much damage is done. This chipping can also create hazardous foreign object debris (FOD).

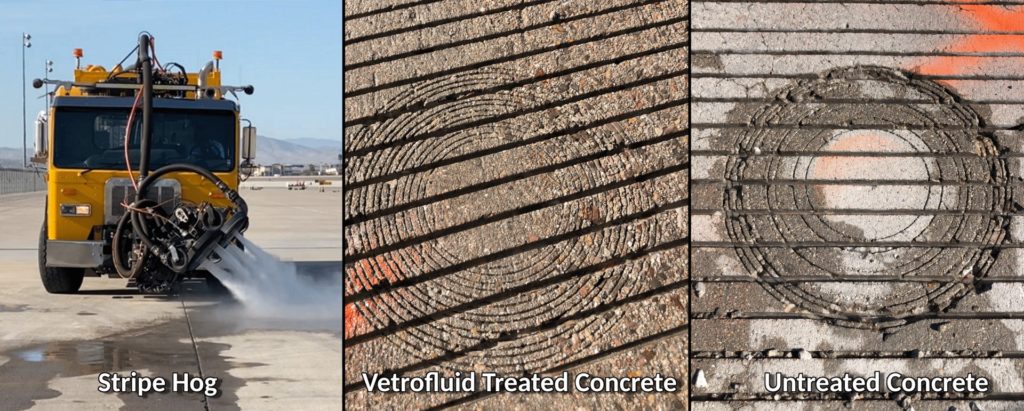

One of these tests was performed on the 24 year old runway shown above. This runway had undergone years of Stripe Hog rubber removal operations , typically at 36,000 PSI. The damage to the touchdown surface and the grooved areas from years of use and maintenance was plainly obvious. For this test, 4 runway panels were selected and cleaned, and 2 were treated with Vetrofluid.

After curing and being used for 6 weeks the Stripe Hog was brought back for testing. Both the treated and untreated panels were tested at 36,000 PSI and the speed was regulated and closely recorded to determine overall performance. Vetrofluid was shown to reduce the rubber removal time by 25%!

This test is currently ongoing so that durability performance can also be recorded.

Paint Removal Protection Too - Without Normal-Wear Delamination

Paint removal tests were also performed and have shown:

- Reduced removal time

- More thorough cleaning of marking paint

- Prevention of micro-cracking under PCC marking paint

- No delamination in wear tests at 4,000 PSI